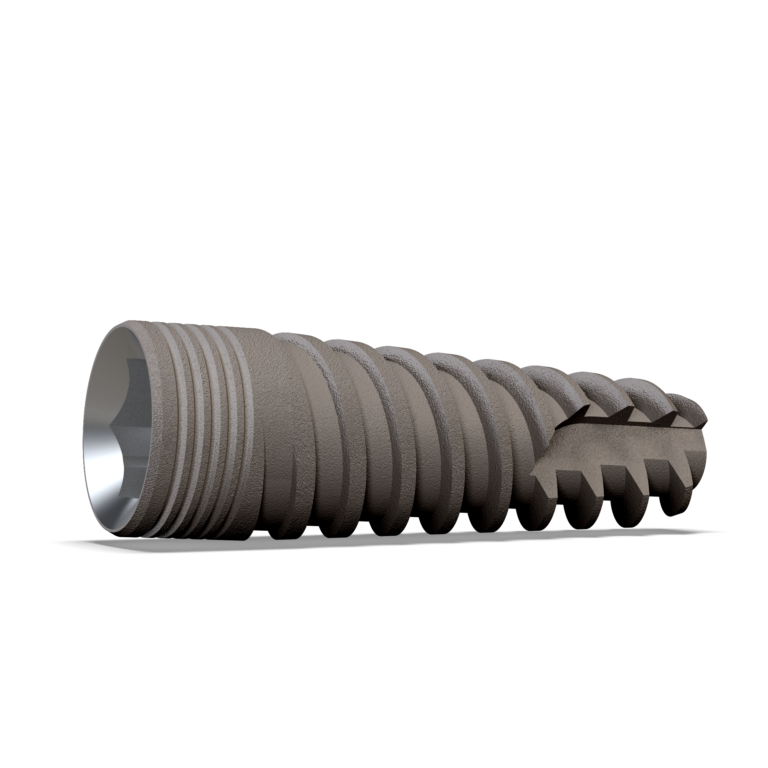

Titanium has been the dominant material in endosseous dental implantology since the 1970s, following the work of Per-Ingvar Brånemark, who discovered titanium’s ability to form a direct and stable interface with bone – a phenomenon he termed osseointegration. Since then, titanium has become the main material of choice for implants due to its excellent corrosion resistance, mechanical reliability, and biocompatibility.

Titanium is available in commercially pure forms (Grades 1-4) and in alloyed forms, most notably Ti-6Al-4V (Grade 5) and Ti-6Al-4V ELI (Grade 23). The grade used has a direct impact on implant performance – affecting tensile strength, fatigue resistance, ductility, machinability, and even biological response.

The Material of Choice in Dental Implants

In dental implants the most used grades are 4, 5, and 23 because they offer an optimal balance between strength and biocompatibility.

-

Grades 1-3: Too soft for most intraoral applications due to lower mechanical strength and fatigue resistance.

-

Grades 6 and above: Rarely used in dentistry due to lack of clinical evidence, excess stiffness, or potentially toxic alloying elements.

Why Do Different Brands Use Different Grades?

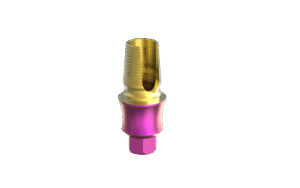

Different brands choose titanium grades based on the specific design and functional demands of their implant systems. Grade 4 (commercially pure titanium) is preferred for standard implants due to its excellent biocompatibility and easier machining. Grade 5 and Grade 23 (titanium alloys) are selected when higher strength and fatigue resistance are needed—such as in narrow implants, angled abutments, or thin-walled components. Some brands use only Grade 4 for simplicity and marketing, while others combine materials depending on the component’s role. Ultimately, the choice reflects a balance between performance, cost, and clinical indication.

Titanium Grades Summary Table

| Property | Grade 4 | Grade 5 | Grade 23 |

|---|---|---|---|

| Composition | Pure titanium | 6% Al, 4% V | 6% Al, 4% V (ELI spec) |

| Tensile Strength (MPa) | ~550 | ~900 | ~860 |

| Yield Strength (MPa) | ~480 | ~830 | ~795 |

| Modulus of Elasticity (GPa) | ~105 | ~110 | ~105–110 |

| Elongation at Break (%) | 15 | 10–15 | 14–15 |

| Fatigue Resistance | Moderate | High | Very High |

| Biocompatibility | Excellent | Good | Excellent |

Implant Companies Marketing Claims

Many manufacturers make overstated or misleading claims based on the titanium grade they use. Statements like “only pure titanium is safe” or “Grade 5 is the strongest and therefore the best” are often oversimplified and unsupported by evidence.

In reality – There is no single “best” grade of titanium for all clinical scenarios. Biological outcomes are more influenced by surface treatment, surgical protocol, and patient-specific risk factors than by small differences in alloy content.

So the next time you hear a dentist says he wants only “pure titanium because it’s better” – send him to this article 🙂

References

-

Brånemark P-I, et al. Osseointegrated implants in the treatment of the edentulous jaw. Scand J Plast Reconstr Surg Suppl. 1977;16:1–132.

-

Elias CN, Lima JHC, Valiev R, Meyers MA. Biomedical applications of titanium and its alloys. JOM. 2008;60(3):46–49.

-

Geetha M, Singh AK, Asokamani R, Gogia AK. Ti based biomaterials, the ultimate choice for orthopaedic implants – A review. Prog Mater Sci. 2009;54(3):397–425.

-

Lausmaa J. Surface spectroscopic characterization of titanium implant materials. J Electron Spectros Relat Phenom. 1996;81(3):343–361.

-

Sidambe AT. Biocompatibility of advanced manufactured titanium implants – A review. Materials. 2014;7(12):8168–8188.

-

Long M, Rack HJ. Titanium alloys in total joint replacement—a materials science perspective. Biomaterials. 1998;19(18):1621–1639.

-

Navarro M, et al. Biomaterials in orthopaedics. J R Soc Interface. 2008;5(27):1137–1158.