Drill Wear and Its Effect on Osseointegration: A Scientific Review

By Nitzan Levy for MSDI Implants Academy | July 24, 2025

Let’s get straight to the point: You’re probably not replacing your drills as often as you should.

Studies show that significant wear can appear after as few as 30 drilling and sterilization cycles! [2, 3].

When drills are used beyond recommended limits, this leads to problems like imprecise cutting, excessive heat generation, and increased risk of implant failure [1,5,6].

How does it happen, and why does it matter? Let’s turn to the latest research for answers.

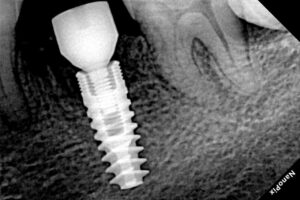

How Drills Affect Osseointegration

Osseointegration, the process of bone integrating with an implant, can be compromised if the drill is not performing at its best.

Worn drills, poor drilling technique, or improper cooling can cause thermal injury to the bone, resulting in bone cell death and impaired healing. Maintaining drill condition and surgical technique is now recognized as essential for predictable implant success, not just a technical detail [1,5].

What Happens When Drills Wear Out?

Drills are not built to last forever. With each use, their edges dull, the cutting geometry deforms, and friction increases – which results more heat.

Once bone temperature exceeds 47°C for more than one minute, there is a real risk of bone necrosis and poor osseointegration [1,7,8].

DLC Coated Drills vs. Regular Drills

Recent in vitro studies confirm that DLC (diamond-like carbon) coated drills improve wear resistance and performance compared to regular, uncoated drills [7,8].

These coatings help maintain sharpness longer and reduce surface damage, even with repeated use.

However, heat generation and drilling speed remain largely unaffected under standard clinical conditions. Both coated and regular drills will still wear over time, and coatings mainly delay, rather than eliminate, degradation.

All drills, regardless of coating, require regular inspection and timely replacement.

The Key to Healthy Bone: Practical Recommendations

As we already know, bone is highly sensitive to thermal damage during implant site preparation. To minimize risk and ensure optimal results, we recommend the following:

-

Use generous irrigation – Keeps bone temperature lower [1,5,6]

-

Apply light, intermittent pressure – Prevents excess heat buildup [1,5]

-

Avoid rushing – Skipping steps or drilling aggressively can harm the bone’s healing capacity [1,5]

- Do not overuse drills – Replace as soon as there are any signs of wear or performance loss [2,3,1].

Final Thought

Drill wear, technique, and thermal control are not minor technicalities – they are core factors affecting your implant outcomes.

If you’re having unexpected failures or bone loss, we recommend to check your drills, as they might be the cause of the problem.

Replace drills in a timely fashion, adjust your approach per case demand, and prioritize thermal management to protect bone and optimize success.

References

-

Sorgato M, Bottin A, Stocchero M, Toia M, Savio E.

“Impact of drill bit wear on temperature increase in dental implant osteotomy: an in vitro study.”

PLoS ONE. 2025; 20(5): e0319492.

Read: https://journals.plos.org/plosone/article?id=10.1371%2Fjournal.pone.0319492 -

Alevizakos V, et al.

“Effects of repeated use and sterilization on the wear of zirconia implant drills.”

Clin Exp Dent Res. 2024; 10.1002/cre2.70088.

Read: https://pubmed.ncbi.nlm.nih.gov/39940099/ -

Alevizakos V, et al.

“Effects of repeated use and sterilization on the wear of zirconia implant drills.”

Clin Exp Dent Res. 2024; Article e70088.

Read: https://onlinelibrary.wiley.com/doi/full/10.1002/cre2.70088 -

Möhlhenrich SC, et al.

“Heat generation and drill wear during dental implant site preparation.”

Int J Oral Maxillofac Implants. 2015; 30(6): 1379-1386.

Read: https://pubmed.ncbi.nlm.nih.gov/26523727/ -

Guimarães CLA, et al.

“Drills physical changes after osteotomies and sterilization: An SEM and energy-dispersive X-ray spectrometry study.”

J Appl Oral Sci. 2024; 32: e20230218.

Read: https://pubmed.ncbi.nlm.nih.gov/40106457/ -

Stocchero M, Toia M, Bottin A, et al.

“The effects of implant drill wear on bone and drilling temperatures: SEM, EDS, and infrared thermography analysis.”

Journal of Biomedical Materials Research Part B: Applied Biomaterials. 2023.

Read: https://pmc.ncbi.nlm.nih.gov/articles/PMC11922234/ -

Er N, Alkan A, Ilday S, Bengu E.

“Improved dental implant drill durability and performance using heat and wear resistant protective coatings.”

J Oral Implantol. 2018; 44(1): 46-50.

Read: https://pubmed.ncbi.nlm.nih.gov/29498904/ -

Bozkurt A, et al.

“A comparison of diamond-like carbon coated and uncoated implant drills: an in vitro study on heat generation and wear behavior.”

Bilkent University Institutional Repository. 2022.

Read: https://repository.bilkent.edu.tr/server/api/core/bitstreams/4e5ceead-da19-4a2e-969f-94277df68819/content